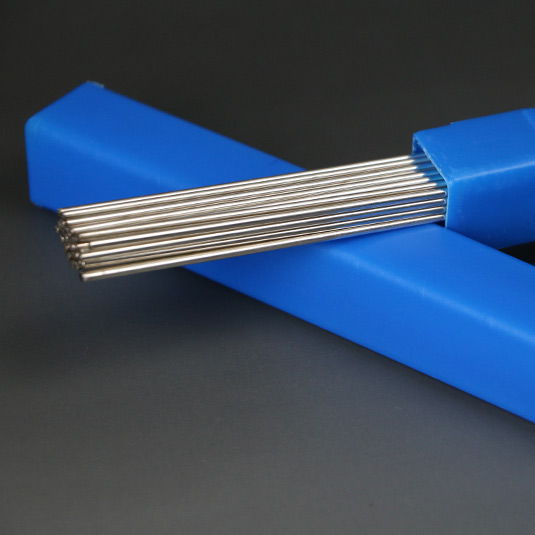

Select your classic silver-based brazing alloy from a range of silver content. High mechanical strength, fine plasticity, electrical conductivity, and corrosion resistance.

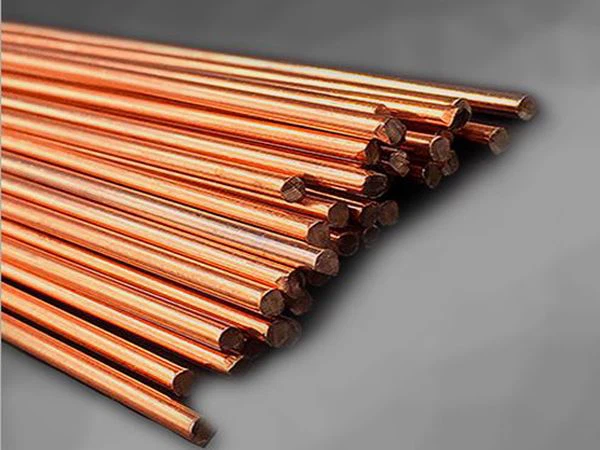

Copper brazing alloys are well known for their excellent resistance to corrosion, high electrical conductivity, and high thermal conductivity and are generally used for brazing carbon and alloy steels, stainless steel, nickel, and copper-nickel. Copper alloys are ductile, wet iron appropriately, and exhibit excellent joint penetration.

Low temperature aluminium solder is a new type of low temperature aluminium welding material with zinc and aluminium alloys. Its melting point is generally 350-450 degrees. It is suitable for welding aluminium and aluminium alloy, aluminium and copper.

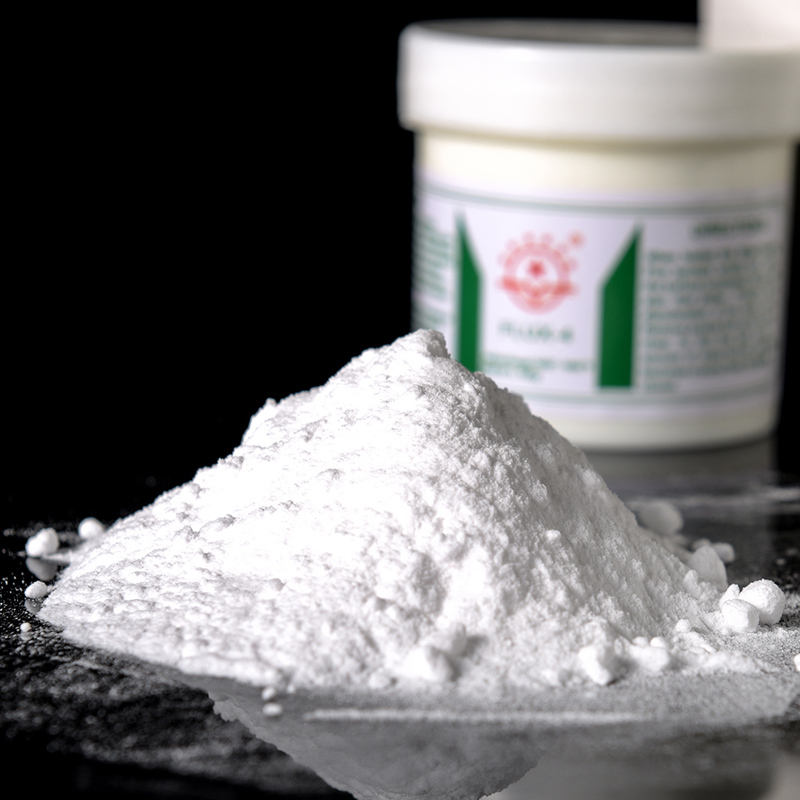

Flux is a kind of chemical material used for brazing, and it is commonly used as welding auxiliary material in general industry. Generally, any metal material will form certain oxide on the surface of air, which will make the solder and base metal not weld together. The main function of flux is to remove the base metal by chemical reaction during brazing process, after melting at high temperature. The dense oxide film on the surface promotes the flow of solder on the base metal, so that the base metal that needs to be welded can truly become an integral whole.